IRON BRIDGE MAP

FIRST LARGE-SCALE CAST-IRON BRIDGE MAP

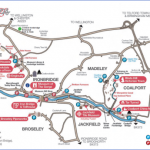

Crossing Severn River, Coalbrookdale, England Designers/Engineers Abraham Darby III, Thomas Farnolls Pritchard Completed 1779 Length 100 feet (30 meters)

Material Iron Type Arch

A rural bridge contains the seeds of the Industrial Revolution.

The Iron Bridge at Coalbrookdale is a seminal bridge. Its arch design was not revolutionary, nor was it the first bridge to use iron in its construction. However, as the first major structure to be constructed entirely of iron, it endures as the earliest portent of the Industrial Revolution, which originated in Great Britain in the late eighteenth century. Two innovations of this new age, the steam engine and ironplentiful, cheap, far stronger than wood, more flexible than stone triggered interconnected economic, technical, and social developments that would alter the world irrevocably.

The Severn River meanders through the picturesque town of Coalbrookdale in Shropshire, where iron was first smelted with coke in 1709. To replace a ferry crossing there, Thomas Farnolls Pritchard (1723-1777) drew up a plan for a cast-iron arch bridge composed of five nearly semicircular ribs supporting an iron roadway 24 feet (7.3 meters) wide. Abraham Darby III (1750-1791), a third-generation master ironworker, suggested to Pritchard that iron would be a stronger and less weighty alternative to stone or wood. There is some dispute among historians as to who actually drew up the final plans for the bridge, as Pritchard died shortly after it was commissioned. In any case, Darby took control of the construction process. [Iron Bridge] is designed in the spirit of masonry, while the detailing of the members is unmistakably that of contemporary timber construction.

IRON BRIDGE MAP Photo Gallery

ROBERTMAGUIRE AND PETER MATTHEWS, “THE IRONBRIDGE AT COALBROOKDALE,” ARCHITECTURAL ASSOCIATION JOURNAL, 1958

This Bridge Was Cast at Coalbrook Dale and Erected in The Year mdcclxxix. So reads the inscription on the bridge’s outer ribs. Nearly 400 tons (363 tonnes) of cast iron, some 800 separate castings in all, were floated down the river and assembled in the course of three months. Completed in 1779, the bridge has a 100-foot (30-meter) span and a total length of 196 feet (60 meters).

The construction methods were not particularly innovative; with a few modifications, the techniques used were the same as those used in building timber or masonry bridges. No bolts were used in joining the metal, and, as in timber bridges, the sections of the bridge are held together with screws.

The bridge has long been the object of artistic pilgrimage. William Williams painted this view in 1780. Iron’s potential was not yet understood. But when Iron Bridge proved to be the only bridge that survived the Severn River flood of 1795, Thomas Telford, the unparalleled engineer of that era, took notice (see here). He recognized the superior strength of iron and from then on worked only in that material.

In 1934 Iron Bridge was declared an “ancient monument” and closed to vehicular traffic. After years of neglect, the bridge is now the centerpiece of a complex of ten industrial museums that commemorate Coalbrookdale as the cradle of the Industrial Revolution. The entire Ironbridge Gorge district was inscribed to UNESCO’s World Heritage List in 1986. What happened here transformed civilization.

The timber-like detailing of the iron members can be seen clearly: dovetails, mortises, wedges, and screws appear in profusion.

I heard him then, for I had just

To keep the Menai Bridge from rust

By boiling it in wine.

Maybe You Like Them Too

- Explore Doncaster, United Kingdom with this detailed map

- Explore Arroyito, Argentina with this Detailed Map

- Explore Belin, Romania with this detailed map

- Explore Almudévar, Spain with this detailed map

- Explore Aguarón, Spain with this detailed map